Embracing Kaizen: Excellence Through Continuous Innovation

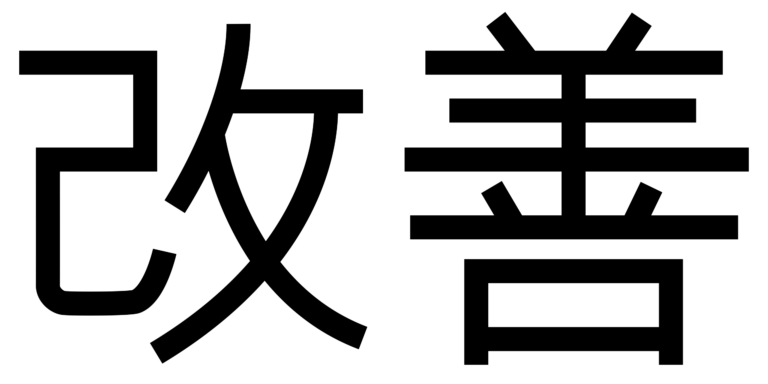

Kaizen is a Japanese word that loosely translates to “Good Change” or “change for the better” in English. It is a philosophy for continuous improvement in the pursuit of excellence.

Masaki Imai popularized the Kaizen philosophy with his 1986 book titled “Kaizen: The Key To Japanese Competitive Success”. It advocates making small incremental changes over time, as an easier way to achieve productivity, efficiency, and quality improvements.

The Kaizen way works for engineering, production, service-based businesses, and even personal development and many other areas of life. This post shows you how your business can achieve excellence by embracing the Kaizen principles of continuous innovation.

Kaizen Vs Innovation

At the core of the Kaizen philosophy lies the human condition – we are emotional beings that often act irrationally. The reason is that the human brain is wired to enter the Fight or Flight mode whenever it senses fearful emotions, such as change. This mechanism is handled by the brain’s amygdala and is a helpful survival mechanism. But on the downside, it often makes innovation difficult for humans.

Innovation here refers to radical change in a business or other setting. A request to commit to a major change usually triggers that human fear response or anxiety, which activates the mid-brain and keeps that person emotional about the issue. In effect, these emotions bypass the neocortex that handles the rational thinking and logic necessary for such a job.

Kaizen, on the other hand, advocates small changes that are emotionally insignificant. This approach keeps the person in a level-headed, rational state of mind and makes it easier to create continuous improvements in both professional and personal environments. Kaizen believes that no process can be perfect, as there will always be room for improvement. This lays the foundation for achieving excellence through continuous learning and growth.

The Promise of A Good Change

The Kaizen philosophy has birthed many management systems that are used by countless successful and global brands to achieve excellence in their various fields.

From Toyota’s Just-In-Time production system to applications in hospitals, software development, airports, supermarkets, and many other industries, Kaizen lies at the core of the Lean thinking and production culture.

Kaizen is a management approach that aims to achieve great feats through discipline and patience. Slowly chipping at your goals through gradual process improvement and a long-term strategy, provides a non-technological and often cheaper approach to innovation.

This was how the Japanese manufacturing industry achieved substantial improvements in product quality and cost reductions through the 1960s and 70s, leading to Masaaki Imai’s classic book.

Key Kaizen Principles

The principles of Kaizen form the foundation upon which the movement and its many variations are built. Here are the major ones that you need to know.

- Continuous Improvement: Kaizen emphasizes the pursuit of excellence by making small but continuous improvements over time. Because, although it is impossible to attain perfection in any process, it is still possible to attain such a high level of excellence after so many iterations that the result of your efforts starts to look perfect. This process includes continuous reviews, adaptations, and standardization.

- Small, Incremental Changes: Big changes can lead to big problems, because the bigger the required change, the more emotional issues, complexities, capital, and radical operations might be needed to implement it. A small change, on the other hand, is usually no big deal. But when you do it over and again, then the magic of Kaizen happens.

- Employee Empowerment / Gemba: Kaizen understands that only those who are closest to a task or process are in the best position to identify areas for improvement. For instance, only those who use the software tools of a company can best give feedback to make improvements. The same goes for each team member or the employees of a company, everyone has to take part in the company’s problem-solving and decision-making.

- Data-Driven Decisions: Kaizen advocates the collection and analysis of real process data to aid in reaching improvement decisions.

- Process not Result: Kaizen teaches the operator to focus on the process and not on the result. For instance, if the result is a physical product that has defects, then it means that its production process was somehow flawed. This also means that you can only correct the flaw by studying the production process and making necessary changes.

- Focus on Quality: The Kaizen system also focuses on improving the quality of an organization’s outputs by focusing on and improving the processes that create those outputs.

- Standardization: By standardizing its processes, any organization reduces variance, and saves time and costs, while boosting the overall quality of its finished products. Kaizen offers the PDCA/SDCA framework to help in standardizing and iterating a company’s production processes. Depending on the industry, standardization might be as simple as writing a Standard Operating Manual for service workers or creating a tool-aided system that includes specific measurements for each step in the process.

- Elimination of Waste: Kaizen teaches that waste (mudra) is an efficiency and profitability killer. So, it advocates the elimination of the 7 mudras from all of your operations to boost efficiency. These wastes include overproduction, motion, inventory, defects, over-processing, transportation, and waiting. The more you reduce each of these production factors in your organization, the higher your operational efficiency.

- Elimination of Strain: Overburden or strain, also known as muri in Japanese can equally depreciate a company’s outputs. Such an elimination entails using the right tools and capacity for the job, hiring or training qualified professionals, and so on.

- Next Process Is The Customer: This principle ties in well with the quest for top quality. Instead of controlling a product once at the end of its development, the product is controlled for quality at each juncture by treating the next process as a customer. This principle rests the duty of quality control on each preceding process that has to provide the best quality products for its customers (next process) to work on.

Applying Kaizen To Business

Applying Kaizen principles to your business depends on your type of organization and the processes that you need to improve on. So, your business could be a 1-man outfit, a team, or a large organization, but the basic principles remain the same and the application is as follows.

- Foster a Kaizen Culture: Having a Kaizen culture in your organization is very important because it lays the foundation for constant improvement. You need to train the entire team. All employees must be on board and understand that no contribution is too small. Leadership should also commit to holding regular meetings with the entire team to discuss and find solutions.

- Identify The Most Relevant Issues: You will always have issues that you need to work on and improve on. Kaizen advocates the Gemba principle. That is, gathering input from the exact station where work happens. You can also use data analysis, suggestion boxes, customer feedback, performance metrics, and any other solutions to identify improvement solutions. If there are many issues, you can prioritize the tasks using an 80/20 analysis for the best results.

- Run The Kaizen Process: The PDCA/SDCA of Plan-Do-Check-Act / Standardize-Do-Check-Act are the major process cycles, where you make the needed improvements in the organization. SDCA is always done first, so you can create standards, and then subsequent cycles are PDCA. Here is how it works

- Plan/Standardize: To plan here refers to establishing a target for improvement in any area of your business. The Kaizen philosophy demands that there always be a target for improvement and action plans in place to achieve it. On the first run, however, and each time an abnormality occurs, there should be a standardization. The standardization step sets the rules, metrics, or exact steps to be followed each time the work is done. And only after the work process is stabilized, do you now make improvement plans for each cycle or iteration.

- Do: This is simply the process of doing the work by following the standards set in Step 1) above.

- Check: You check the process to determine whether your implementation has achieved the desired results or is still at all on track.

- Act: Refers to performing the new procedure and normalizing it as the standard way of handling such a task in your business.

- Rinse & Repeat: Kaizen is about continuous improvements and innovation, so you need to keep going after each cycle. Or you can equally focus your improvement efforts on another process. Just rinse and repeat.

Applying Kaizen To Daily Life

You can equally apply the Kaizen philosophy in your personal life to get results from activities such as getting fit, eating better, studying, doing work, and reaching diverse goals. The trick here is to focus on small and emotionally irrelevant goals at first. Something that will not stress you out or make you anxious in any way.

For instance, if you want to get fit by jogging, you may set a relatively simple goal of jogging on the spot for just 1 minute a day, and then grow from there. If you want to quit smoking, you can reduce a single stick from your cigarettes each week or month, until you quit. You can also dedicate just 5 minutes to thinking or working on a big or terrifying project until it gets rolling.

The goal is to start with small steps, and then make small, incremental, and continuous changes over time. It works because it cuts out procrastination, anxiety, and other self-sabotaging behaviors that keep people from reaching their goals.

List of Kaizen Phrases & Concepts

Because the Kaizen philosophy originated in Japan, you will find a lot of Japanese terms in constant use with it. Here is a quick list of major Kaizen terms and their meanings.

5S: The five (5S) of good housekeeping are as follows.

- Seiri (Sort): Classify items, keep the necessary items, and discard the unnecessary items.

- Seiton (Straighten): Organize your tools according to use to minimize time and effort.

- Seiso (Scrub): Clean and keep your workplace clean.

- Seiketsu (Systematize): Follow the system, and use the right tools, protection, and gear.

- Shitsuke (Standardize): Maintain self-discipline.

Muda: Muda means waste and there are 7 mudas or wastes, as follows.

- Overproduction: Producing more than needed is a waste.

- Inventory: Lots of finished or unfinished products in the inventory add no value.

- Defects: Each defective product is a waste of resources.

- Motion: Physical exertion that does not add value to the product is a waste.

- Over-processing: A wrong and un-optimized processing approach can be wasteful.

- Waiting: An idle operator is a waste.

- Transport: The more a product is transported, the more waste is created.

Gemba: The place where things or work happens. Every manager needs a first-hand experience.

Muri: (Overburden) A strenuous situation. Like giving a new employee the job of a veteran worker without first providing him with proper training.

Mura: (Variation) This happens when the smooth flow of work is stopped due to slight differences in the task or time spent on the process. Standardization takes care of this.

Jidoka: Automation

Organizations That Use Kaizen

Lots of big and small organizations that you know employ Kaizen principles in their operations. They include everyone from Toyota to Sony, Canon, Panasonic, Honda, Samsung, Nestle, ABB, Ford, Lockheed Martin, Toshiba, Mayo Clinic, Societe General, Unilever, Tchibo, Cadburry-Schweppes, and governments like the United Arab Emirates, Mauritius, Kenya, and India.

Of course, the list goes on.

Frequently Asked Questions

Here are some frequently asked questions related to the Kaizen methodology and continuous innovation.

What are the benefits of Kaizen?

Kaizen is an easy-to-implement improvement methodology that is less disruptive and often less capital-intensive than other methods.

Will Kaizen work in my business?

Most definitely, yes. So long as your business relies on processes to create value for customers, you can successfully implement Kaizen on it.

What are the differences between Kaizen and Lean?

Both are similar because they focus on continuous improvement, elimination of waste, and efficiency improvements. Kaizen, however, is a deeper and broader philosophy, upon which Lean is built.

Can Kaizen be implemented alongside other innovation systems?

Yes it can.

Conclusion

Wrapping up this quick guide on the principles of Kaizen and how they can help you to achieve excellence in your business through continuous innovation, you should have an idea or two by now, of how to implement some changes.

Kaizen is a guiding philosophy and its methods are not set in stone. But when you follow its guidance and embark on your journey of continuous transformation, then you will surely achieve excellence.